1/13/2025

To follow up on the previous blog post –

I GOT THE HEATER WORKING!

Here’s where my assumptions were correct & not:

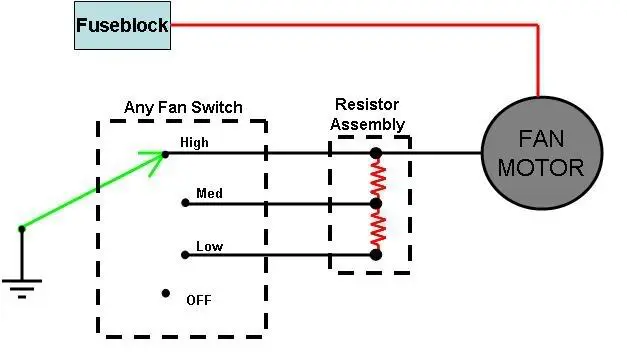

The drawing above is far more accurate (and concise) than my previous flowchart.

Incorrect assumption 1: The BLOWER motor does NOT connect directly back to the SWITCH. It goes through RESISTOR first, and is electrically bypassed for HIGH.

Incorrect assumption 2: The SWITCH does not have any cabling which GROUNDs it. It grounds to the dash when screwed in.

Ask me how I know?

Because the goddamn thing didn’t work until I DROPPED IT ON THE STEEL FLOORPAN. Then magically we had a functioning heater.

Go figure. Grounding. Again.

Coming Soon

Remember how we’ve long speculated that Emma might have a mild after-market cam in the engine?

There are a couple of way to find out if that’s true – and if true, changes the entire course of how we tune her.

We could:

Lift Engine

Drain fluids

- Coolant

- Oil

Remove top-end

- Intake manifold

- Valve covers

- Rocker arms

- Pushrods

Remove lifters

- Pull all lifters out of their bores

- They must be out or the cam won’t move

Strip the front of the engine

- Water pump

- Crank pulley / harmonic balancer

- Timing cover

Remove timing set

- Rotate engine to TDC

- Remove cam gear and timing chain

- Remove cam thrust plate

Slide camshaft out

Orrrrrrr…. we could

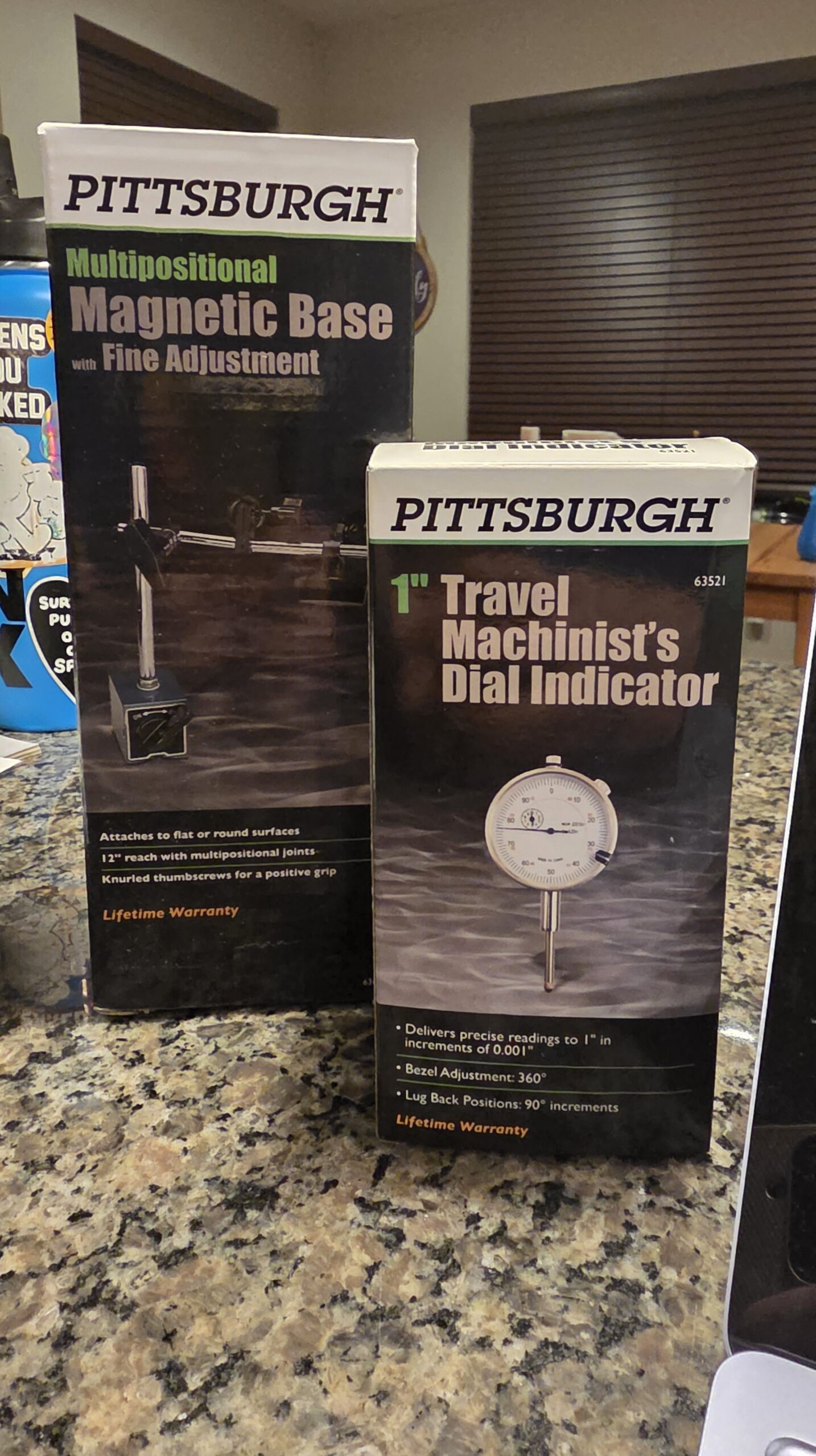

Supposedly using a machinist’s dial is the easiest way to determine cam, based on the amount of lift on a single rocker (retainer) with one engine rotation.

Under ~0.420″ valve lift → probably stock

0.440″+ → very likely aftermarket

0.480″+ → definitely aftermarket

Sounds good to me!

Leave a Reply